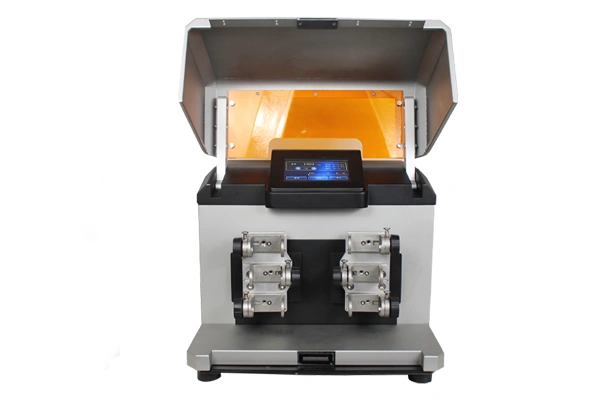

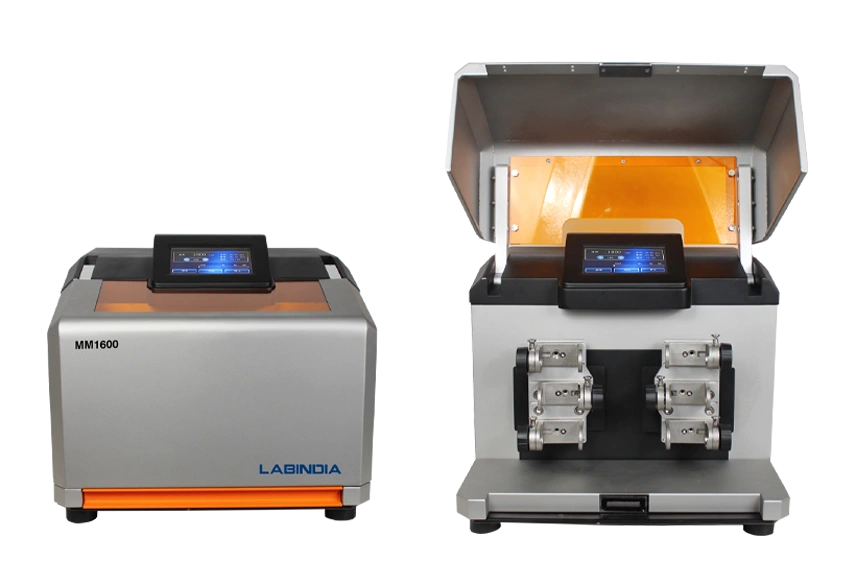

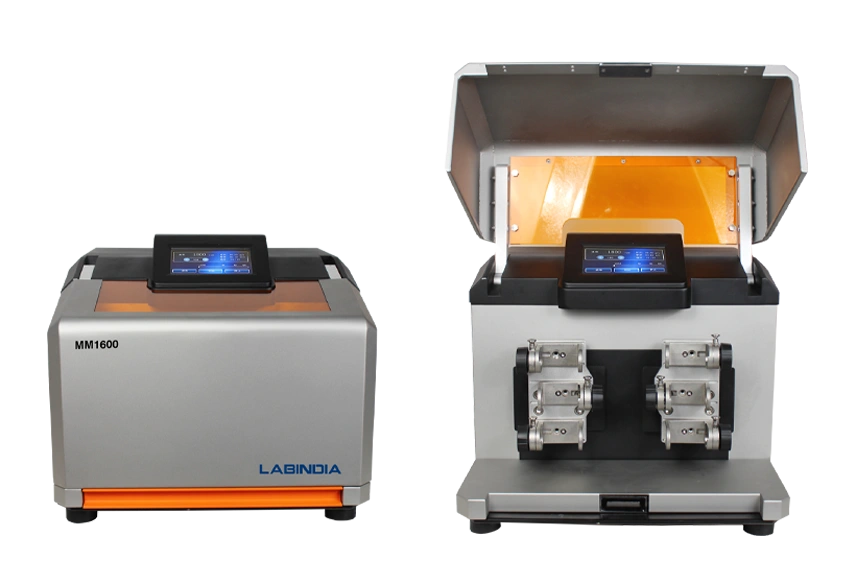

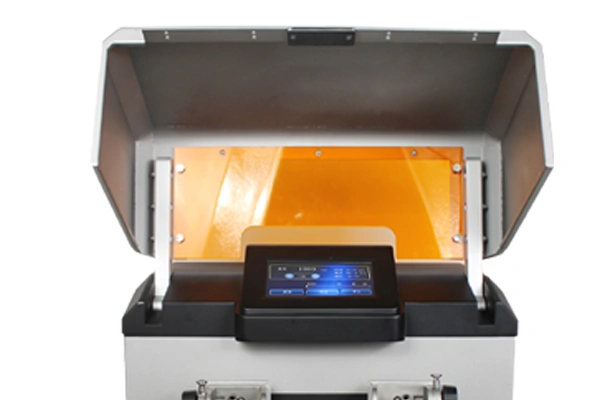

High Energy Ball Mill MM1600

The LABINDIA High Energy Ball Mill MM1600 is a powerful, multi-functional benchtop ball mill designed for fast and efficient preparation of ultra-fine samples. Capable of handling up to 384 samples simultaneously, it supports dry, wet, and cryogenic grinding for a wide range of materials.This high-throughput mill is ideal for grinding, mixing, and homogenizing hard, soft, brittle, elastic,and fibrous samples down to the nanometer scale in seconds.

Suggested Products

- AIR JET SIEVE SHAKER JS1100 (TOUCHSCREEN)

- Vibratory Disc Mill VDM 1100

- Bomb Calorimeter – BCI-3000

HIGH-THROUGHPUT GRINDING

The MM1600 is designed for large sample volumes, accommodating grinding jars ranging from 1.5 ml to 125 ml, with a variety of materials including stainless steel, zirconium oxide, tungsten carbide, and PTFE. The system’s advanced grinding mechanism ensures high efficiency, whether working with dry, wet, or cryogenic conditions. Additionally, the Cryo Kit facilitates cooling with liquid nitrogen for temperature-sensitive samples.

Key Features

Equipped with a 7” LED color touchscreen, the MM1600 offers intuitive control over grinding parameters, such as speed, time, and cycle settings. It allows for the storage of up to 20 sets of standard operating procedures (SOPs), enabling consistent results. The machine’s safety features include a lock device to stop operation when the lid is opened, ensuring user protection during grinding.

ADVANCED CONTROLS & SAFETY