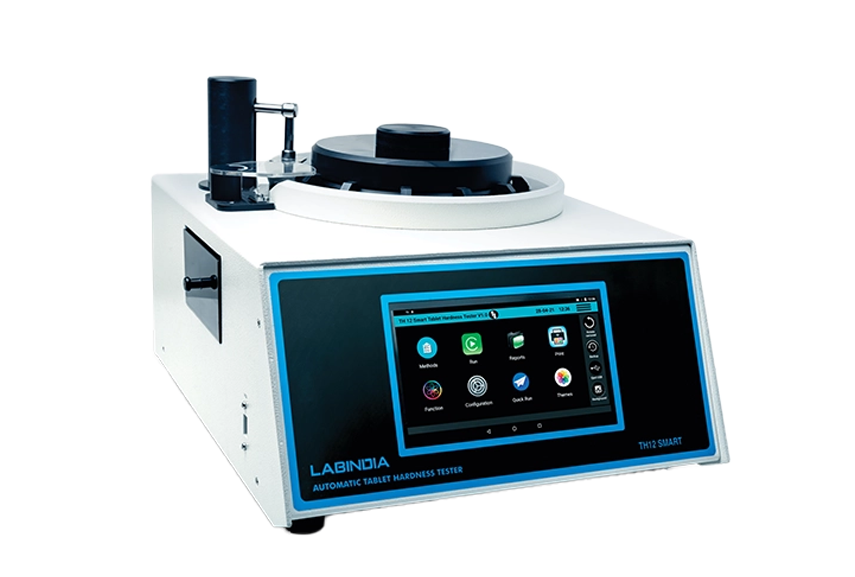

Tablet Hardness Tester TH 2050S

The Tablet Hardness Tester TH 2050S features an advanced 24-point carousel system, designed for automatic measurement of essential tablet parameters such as Thickness, Width, Length/Diameter, Weight, and Hardness. With the ability to test up to 20 tablets in a single run, it meets Pharmacopeial requirements and offers unmatched efficiency for quality control testing.

Suggested Products

- Leak Tester LT600

- Tablet Hardness Tester - (TH 12 SMART)

- Tablet Dissolution Tester DS 8000 SMART with Piston Pump

AUTOMATIC MEASUREMENT

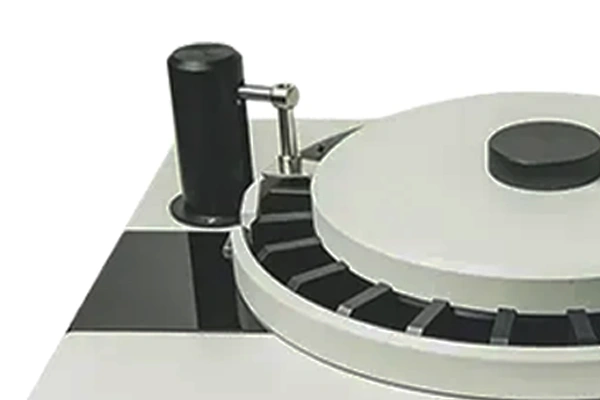

This system simplifies testing with its 24-position carousel, allowing users to automatically measure key tablet properties. The device's sweeping blades clean the tablet path, removing any broken pieces, debris, or dust, ensuring accurate results every time.

Key Features

With a large non-volatile memory, the TH 2050S stores up to 99 methods and results, including validation and calibration data. The generated reports are GLP-compliant, ensuring full traceability and compliance with industry standards.

LARGE DATA STORAGE & REPORTING

USER-FRIENDLY OPERATION

Equipped with an intuitive micro-controller-based interface and waterproof polyester soft keys, the tester provides an easy-to-use environment for operators. The dialogue-mode software ensures smooth operation with built-in protections against invalid entries.

Linear displacement speed is fully customizable, offering flexibility to meet different testing needs. The tester can automatically run tests for up to 100 tablets, with the ability to restart from the last saved parameters after a power failure or system reset.

FLEXIBLE TESTING OPTIONS