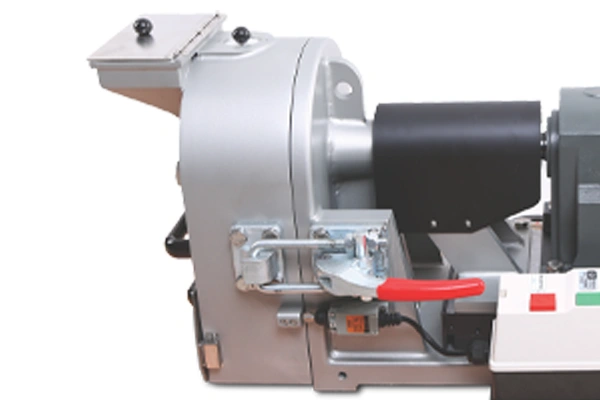

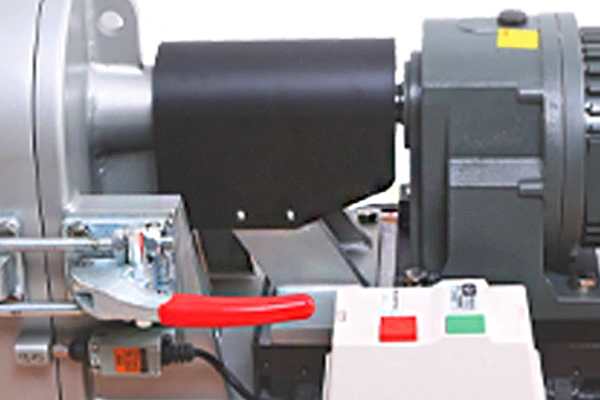

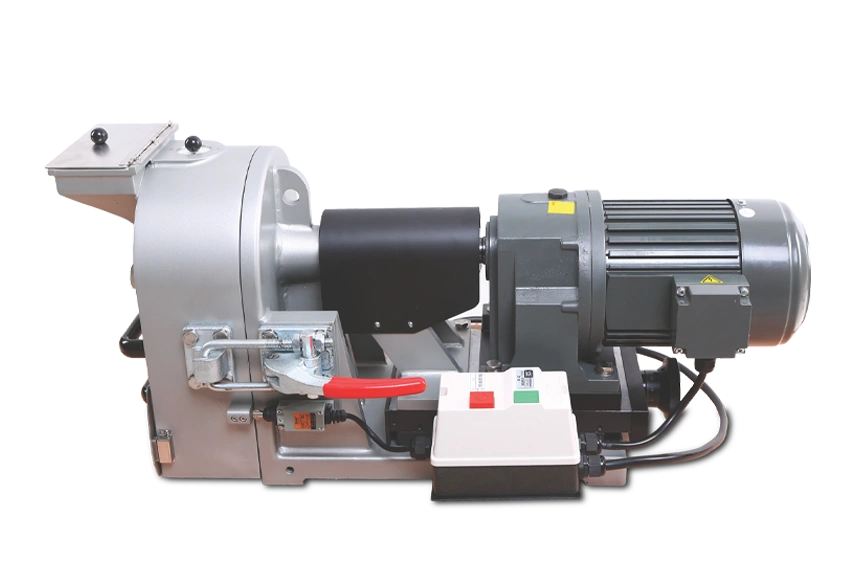

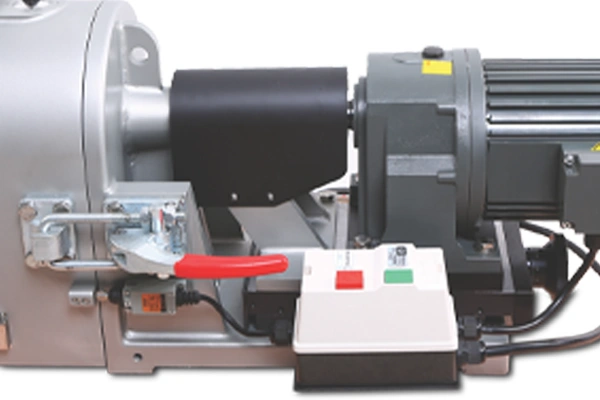

Pulverizer (Disc Mill) DM 1100

The LABINDIA Pulverizer DM 1100 efficiently grinds samples using pressure and friction generated between a rotating and a fixed disc. As the sample enters the grinding chamber, it undergoes preliminary crushing through the progressively arranged teeth of the grinding disc. Centrifugal force then moves the sample to the outer regions for fine grinding. The ground sample is then collected in the sample receiver, ensuring quick and efficient processing.

Suggested Products

- AIR JET SIEVE SHAKER JS1100 (TOUCHSCREEN)

- Vibratory Disc Mill VDM 1100

- Bomb Calorimeter – BCI-3000

EFFICIENT SAMPLE GRINDING

The DM 1100 offers superior grinding performance with the ability to handle sample feed sizes up to 20mm. Its adjustable disc gap allows for precise control over the grinding process, making it ideal for applications requiring fine particle sizes in a short amount of time. With multiple disc material options, the DM 1100 can be customized to suit various sample types while ensuring wear resistance for long-term use.

Key Features

Designed for simplicity, the DM 1100 is easy to operate and clean, making it suitable for high-volume applications. Its large processing capacity and the dust discharge connector help minimize sample contamination, ensuring a cleaner working environment. The digitally displayed disc gap adjustment allows for precise and consistent results every time.

USER-FRIENDLY DESIGN