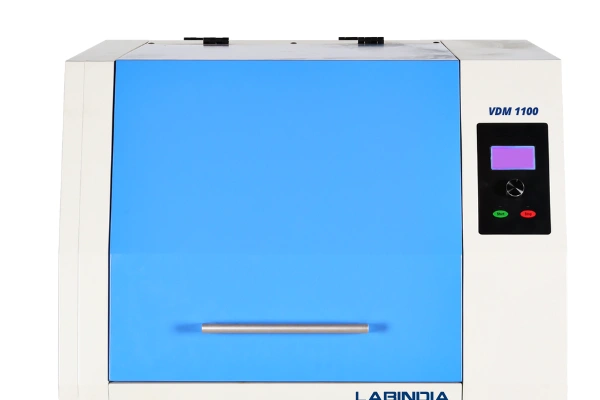

Vibratory Disc Mill VDM 1100

The VDM 1100 Vibratory Disc Mill is designed for rapid sample preparation for spectral analysis. This high-performance device is ideal for grinding medium-hard, hard, brittle, and fibrous materials to analytical fineness without any sample loss. By utilizing pressure, impact, and friction, it ensures efficient grinding for diverse applications such as ceramics, building materials, environmental studies, and metallurgy.

Suggested Products

- AIR JET SIEVE SHAKER JS1100 (TOUCHSCREEN)

- Vibratory Disc Mill VDM 1200

- Bomb Calorimeter – BCI-3000

EFFICIENT GRINDING PERFORMANCE

The VDM 1100 features an advanced vibratory mechanism that generates intense three-dimensional vibrations, creating high-impact grinding forces. With a quick-action clamping device, the grinding set is securely attached, ensuring precise and reproducible results. The mill achieves an exceptional final fineness of 20 µm in minimal time, making it highly efficient for demanding analytical tasks.

Key Features

This versatile instrument offers digital speed control (700–1500 rpm) and is compatible with a range of grinding materials, including hardened steel, stainless steel, agate, tungsten carbide, and zirconium oxide. Automatic recognition of grinding sets, such as agate and tungsten carbide, ensures optimized speed adjustment for specific applications. Its color graphical display and storage for 10 SOPs simplify parameter programming for repeatable workflows.

VERSATILE OPERATION