Planetary Ball Mill BM 1100+ (1 Grinding Station)

The Planetary Ball Mill BM 1100+ is engineered for high-energy grinding, mixing, homogenizing, and colloidal milling. It is designed to handle a wide range of materials, including soft, hard, brittle, andfibrous substances, achieving ultra-fine particle sizes down to <0.1µm. The BM 1100+ is commonly used in applications like plant materials, cement clinker, concrete, charcoal, catalysts, chemicals, alloys, metal oxides, iron ore, ceramics, polymers, and pigments.

Suggested Products

- AIR JET SIEVE SHAKER JS1100 (TOUCHSCREEN)

- Vibratory Disc Mill VDM 1100

- Bomb Calorimeter – BCI-3000

ADVANCED GRINDING CAPABILITIES

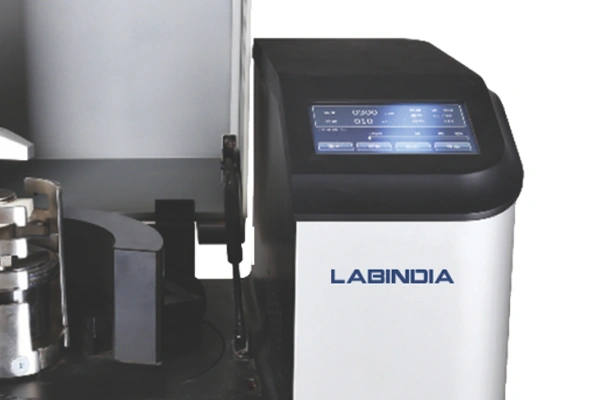

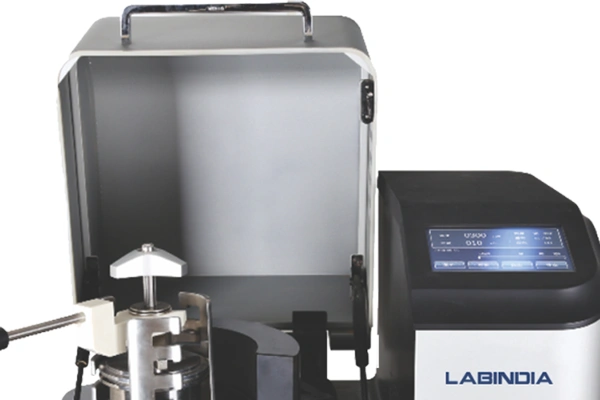

The BM 1100+ delivers fast and efficient grinding, with two grinding modes (dry/wet) and a speed-adjustable sun wheel that operates at 100-650 RPM. It can be used for both pulverizing and mechanical alloying, offering a high energy input for colloidal grinding and alloy preparation. The mill features a 7" LED touch display for easy, digital control of speed, grinding time, and cycle parameters. The machine also supports customizable grinding cycles with settings for holding time, interval operation, and reverse direction.

Key Features

This planetary ball mill includes an automatic ventilation system for cooling the grinding jar and high-power fans to prevent overheating of the motor during operation. With a multi-safety design, the grinding jars are sealed to ensure safe, dust-proof, and gas-tight operation during colloidal grinding. The system also includes intelligent safety locks to prevent accidents during use. Additionally, users can store up to 10 SOPs for consistent, repeatable results.

SAFETY & USER-FRIENDLY DESIGN