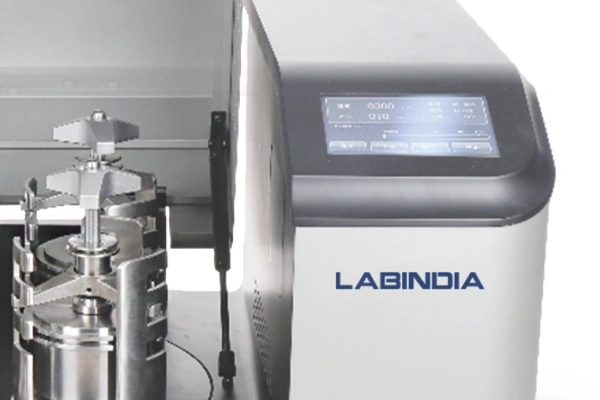

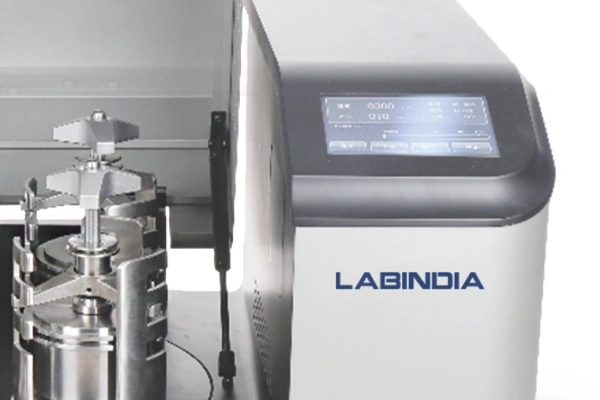

Planetary Ball Mill BM 1400+ (4 Grinding Stations)

The Planetary Ball Mill BM 1400+ is a versatile system designed for mixing, grinding, and colloid milling. With its high energy input, it is capable of producing nano-fineness and is ideal for applications such as alloy preparation, plant material processing, cement clinker grinding, and many others. This mill is particularly

feature-1

feature-2

feature-3

Planetary Ball Mill BM 1400+ (4 Grinding Stations)

The Planetary Ball Mill BM 1400+ is a versatile system designed for mixing, grinding, and colloid milling. With its high energy input, it is capable of producing nano-fineness and is ideal for applications such as alloy preparation, plant material processing, cement clinker grinding, and many others. This mill is particularly

HIGH PERFORMANCE GRINDING

The BM 1400+ offers powerful and quick grinding to nano-fineness, down to less than 0.1 µm. It can handle both dry and wet grinding, with a speed range of 30-400 rpm and a speed ratio of 1:2.2,suitable for a wide variety of applications. The system includes four grinding stations, allowing it to process 2, 4, or 8 samples simultaneously. The intelligent control panel features a 7" touch displaywith digitally adjustable parameters like speed, grinding time, holding time, and interval operation for enhanced user control.

Key Features

The BM 1400+ is equipped with a variety of grinding jars made from different materials such as stainless steel, agate, and tungsten carbide, ensuring contamination-free grinding. Its automatic ventilation system provides effective cooling, preventing overheating during long grinding sessions. The system features multi-safety designs, including gas-tight, dust-proof, and safe operation during colloid grinding, as well as an intelligent security lock for safe use.

VERSATILE & SAFE DESIGN