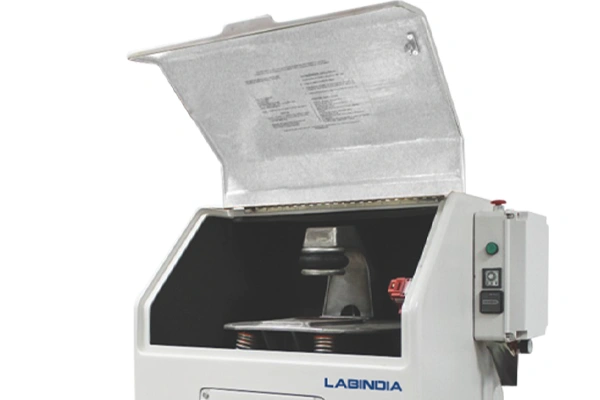

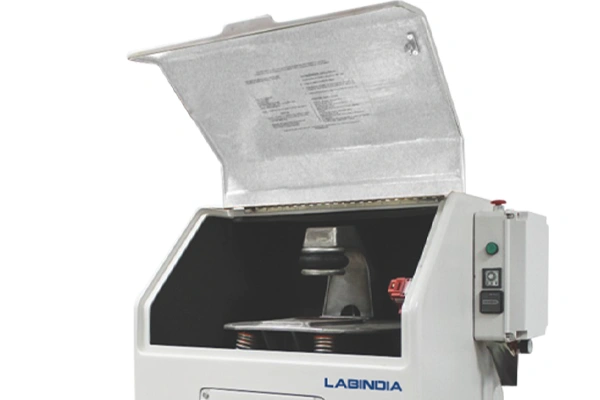

Vibratory Disc Mill VDM 1200

The VDM 1200 Vibratory Disc Mill is a compact and powerful solution for sample preparation in spectral analysis. Designed for fast and precise dry grinding, it handles medium-hard, hard, brittle, and fibrous materials with ease. This mill is suitable for applications across ceramics, building materials, environmental studies, and metallurgy, offering efficient and reproducible grinding for large sample capacities.

feature-1

feature-2

feature-3

Vibratory Disc Mill VDM 1200

The VDM 1200 Vibratory Disc Mill is a compact and powerful solution for sample preparation in spectral analysis. Designed for fast and precise dry grinding, it handles medium-hard, hard, brittle, and fibrous materials with ease. This mill is suitable for applications across ceramics, building materials, environmental studies, and metallurgy, offering efficient and reproducible grinding for large sample capacities.

HIGH-CAPACITY GRINDING

With a processing capacity of up to 1.8 kg per batch, the VDM 1200 ensures high throughput while achieving a final fineness of d95<75>

Key Features

The VDM 1200 features a compact, floor-type design that saves space in the laboratory. Safety is prioritized with a protection lock mechanism, while the quick-action clamping device ensures secure operation. Grinding sets made of hardened steel, tungsten carbide, or high manganese steel offer versatility for various sample types.

USER-CENTRIC DESIGN