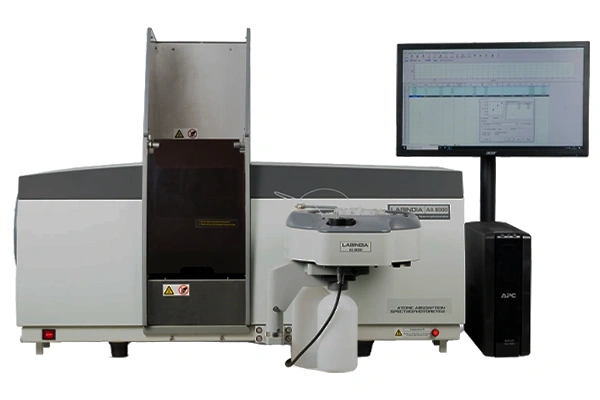

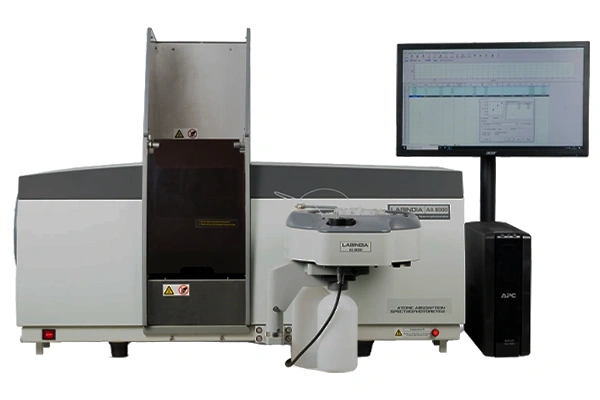

Atomic Absorption Spectrophotometer AA8000

The Fully Automatic True Double Beam Atomic Absorption Spectrophotometer AA8000 by Labindia Analytical provides precise elemental analysis with its true double beam design for superior accuracy and stability. It supports flame, graphite furnace, and vapor generation techniques. Its automated system ensures efficient operation, enhanced by advanced safety features and comprehensive data management, making it ideal for various applications.

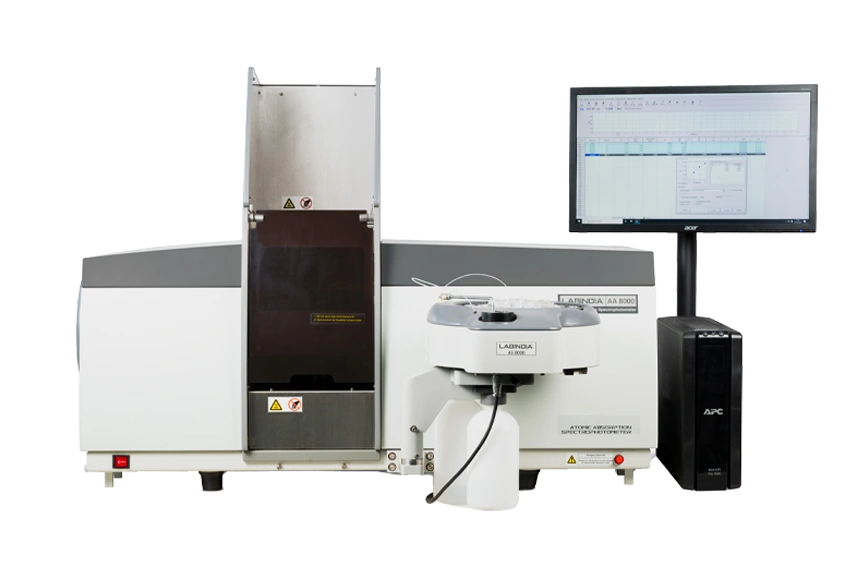

Atomic Absorption Spectrophotometer AA8000

The Fully Automatic True Double Beam Atomic Absorption Spectrophotometer AA8000 by Labindia Analytical provides precise elemental analysis with its true double beam design for superior accuracy and stability. It supports flame, graphite furnace, and vapor generation techniques. Its automated system ensures efficient operation, enhanced by advanced safety features and comprehensive data management, making it ideal for various applications.

Full Automation

The AA8000 offers seamless, automated analysis with an 8-lamp turret, automatic energy alignment, and a universal autosampler compatible with flame and graphite furnace systems. It supports multi-element analysis, maximizing efficiency and precision. The system’s PC-integrated design provides full software control, ensuring GLP and 21-CFR Part 11 compliance for secure and accurate data management.

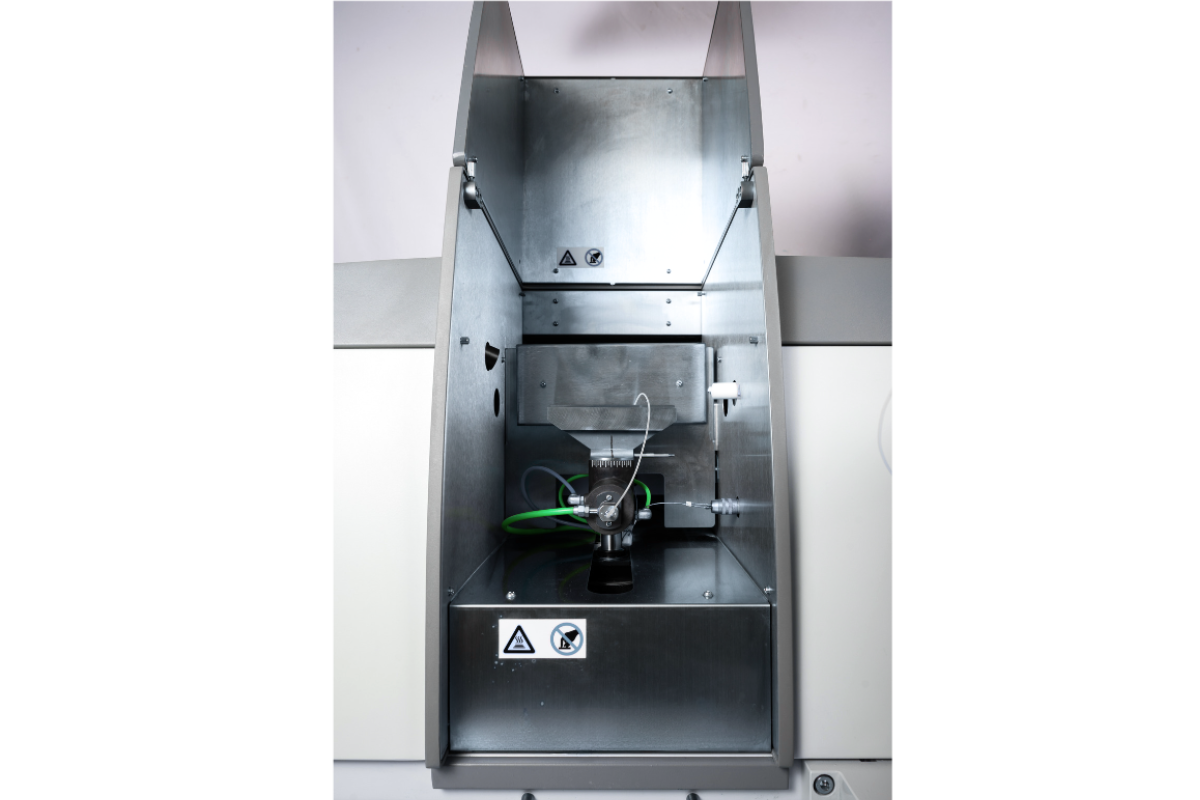

Key Features

Equipped with software-operated mass flow control, the AA8000 optimizes fuel and oxidant ratios, even during external adjustments. Automatic gas flow adjustments ensure stable operations when switching between different gases, enhancing safety and performance.

Advanced Gas Control