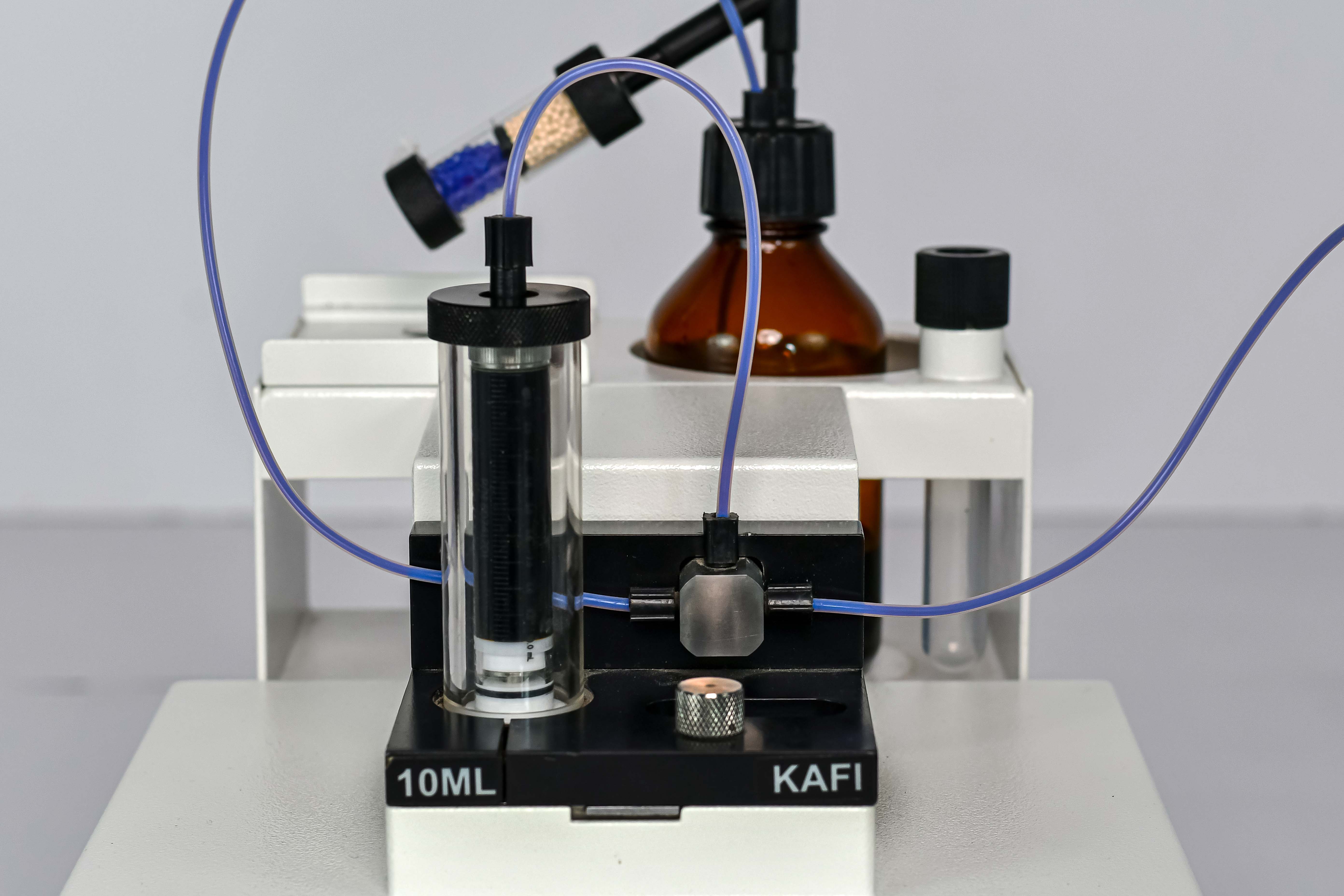

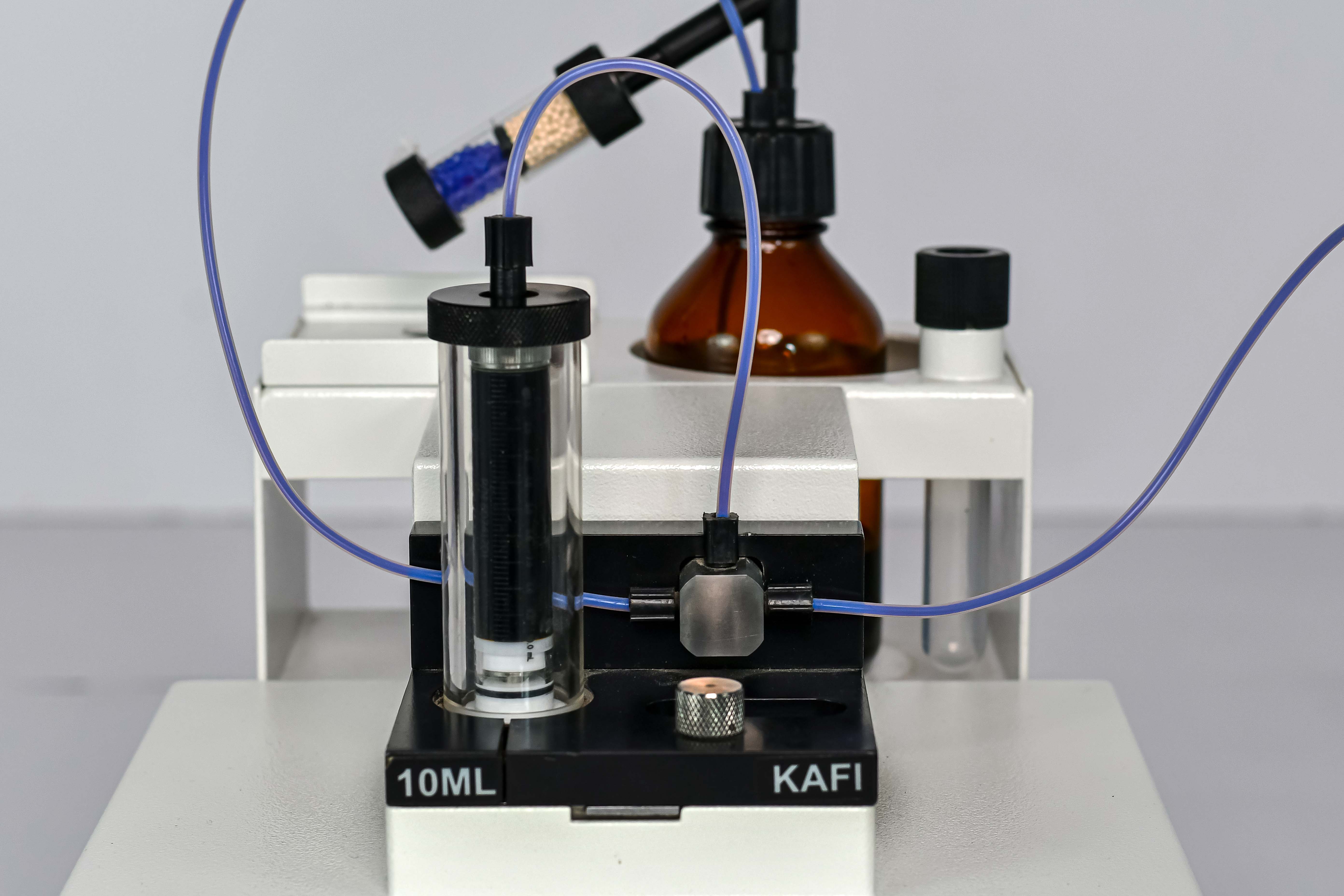

KAFI+ Karl Fischer Titrator

Introducing the Karl Fischer Titrator KAFI+, designed to meet USP/BP/ASTM standards. It features online leak correction to detect any leaks prior to operation. The device can store up to 50 methods and print the last 10 results with all necessary parameters. Equipped with a variable speed magnetic stirrer and a backlit LCD screen, it also includes a dual-password system for method protection. Additionally, it offers PC compatibility and a built-in balance interface for enhanced functionality.

feature-1

feature-2

feature-3

KAFI+ Karl Fischer Titrator

Introducing the Karl Fischer Titrator KAFI+, designed to meet USP/BP/ASTM standards. It features online leak correction to detect any leaks prior to operation. The device can store up to 50 methods and print the last 10 results with all necessary parameters. Equipped with a variable speed magnetic stirrer and a backlit LCD screen, it also includes a dual-password system for method protection. Additionally, it offers PC compatibility and a built-in balance interface for enhanced functionality.

ACCURATE TITRATION CONTROL

Equipped with quick-interchangeable burette assemblies and intelligent volume recognition, the KAFI+ guarantees precise dispensing. It features online leak correction, a variable-speed magnetic stirrer, and supports multiple calculation modes. With the ability to store and reprocess the last ten results, it offers comprehensive reporting, ensuring ASTM standard compliance for oil sample analysis.

Key Features

The Automatic Karl Fischer Titrator (KAFI+) features a sophisticated moisture leak monitoring system that ensures quick detection and automatic neutralization of moisture leaks. This technology keeps the titration vessel ready for subsequent runs, optimizing accuracy and reliability. With microcontroller-based control and a variable-speed magnetic stirrer, the KAFI+ enhances overall performance for precise titration results.

ADVANCED LEAK CORRECTION