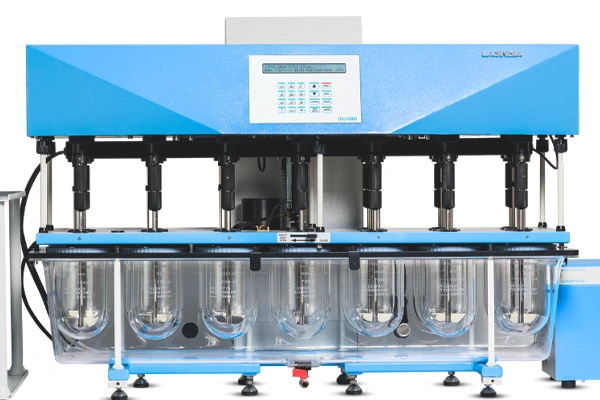

Dissolution Tester DS 14000+ with Syringe Pump

The Labindia Tablet Dissolution Tester DS 14000+ with Syringe Pump offers advanced capabilities for efficient and accurate offline dissolution sampling. This system features a 12-port multi-syringe pump with a proprietary, high-efficiency, maintenance-free stepper motor drive, enabling long-duration testing with consistent performance.

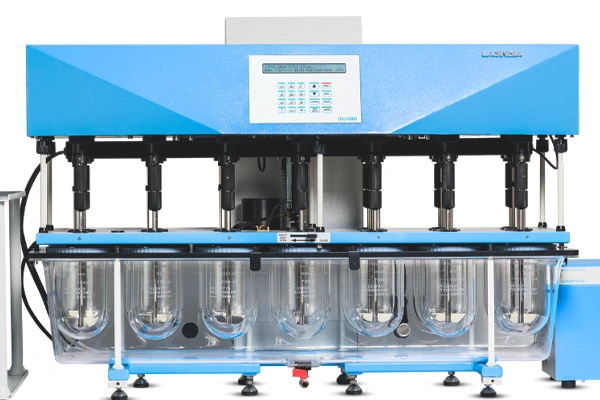

Dissolution Tester DS 14000+ with Syringe Pump

The Labindia Tablet Dissolution Tester DS 14000+ with Syringe Pump offers advanced capabilities for efficient and accurate offline dissolution sampling. This system features a 12-port multi-syringe pump with a proprietary, high-efficiency, maintenance-free stepper motor drive, enabling long-duration testing with consistent performance.

ADVANCED SAMPLING SYSTEM

The DS 14000+ comes equipped with a multi-syringe pump system, allowing for precise and simultaneous sample collection from up to 12 vessels. This ensures reliable, accurate, and timely data collection for all dissolution tests. The system is designed for uninterrupted operation with a robust stepper motor, eliminating the need for frequent maintenance.

Key Features

With the ability to store up to 15 methods, including their parameters, the system ensures that the last run parameters can be retrieved and applied immediately. Furthermore, the system supports dual simultaneous runs under identical conditions, maximizing testing efficiency. In the event of a power failure, the system automatically resumes the dissolution test from where it left off, minimizing any loss of data.

SEAMLESS CONTINUITY

REGULATORY COMPLIANCE

Fully compliant with USP, BP, EP, and IP standards, the DS 14000+ meets all necessary specifications for accurate and reliable dissolution testing. It also adheres to FDA mechanical calibration requirements, ensuring that all tests are conducted with the highest standards of precision and reliability.