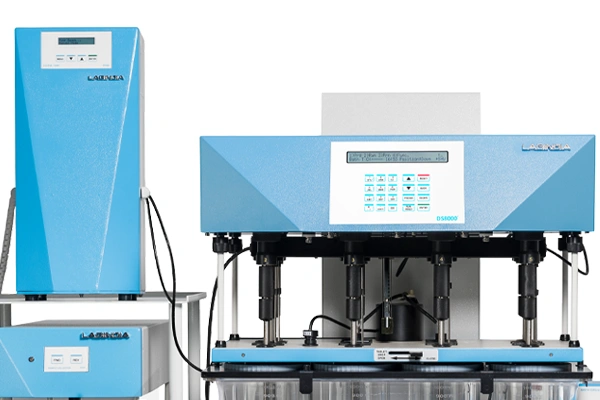

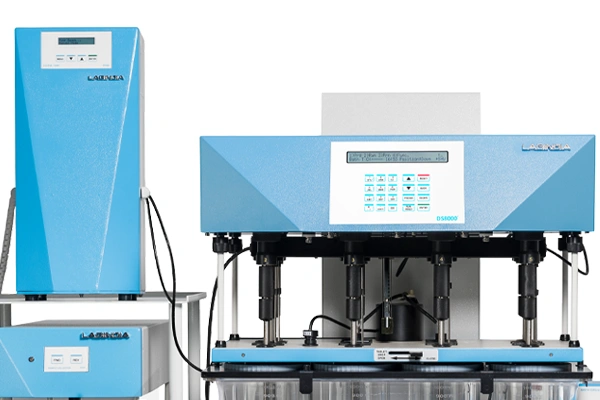

Tablet Dissolution Tester DS 8000+ with Piston Pump & Automatic Filter Changer

The Labindia Tablet Dissolution Tester DS 8000+ with Piston Pump and Automatic Filter Changer is the ideal solution for streamlined dissolution testing. It offers efficient sample collection, filtration, and accurate withdrawal, easing the complex process of pharmaceutical testing. The system integrates a high-pressure piston pump with an automatic filter changer, improving the consistency and speed of analysis.

feature-1

feature-2

feature-3

Tablet Dissolution Tester DS 8000+ with Piston Pump & Automatic Filter Changer

The Labindia Tablet Dissolution Tester DS 8000+ with Piston Pump and Automatic Filter Changer is the ideal solution for streamlined dissolution testing. It offers efficient sample collection, filtration, and accurate withdrawal, easing the complex process of pharmaceutical testing. The system integrates a high-pressure piston pump with an automatic filter changer, improving the consistency and speed of analysis.

Automated Filtration & Sampling

The Automatic Filter Changer (FC 08) is controlled by the dissolution tester and filters up to 8 sampling lines simultaneously. It is compatible with standard 0.45-micron syringe filters, and up to 96 filters can be stored for uninterrupted sample filtration across 16 sampling points.

Key Features

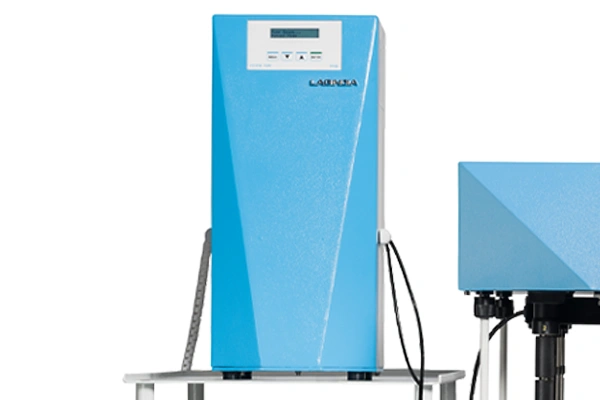

The PP 08 piston pump provides high flow rates up to 25 ml/min with excellent accuracy, while its inert ceramic rotor overcomes absorption issues. The system is ideal for the automated sampling of surfactant media, ensuring precise and reliable results.

High-Performance Piston Pump