Planetary Ball Mill BM1150+ (Two Grinding Stations)

Introducing the LABINDIA Planetary Ball Mill BM1150+, designed for precise dry and wet grinding and mixing of soft, hard, brittle, and fibrous samples. This versatile mill ensures reproducibility of grinding results and meets the highest standards for colloidal grinding. Ideal for a range of applications, including mechanical alloying, the BM1150+ delivers high-energy input and fine grinding to nano levels, making it a key asset in any laboratory.

feature-1

feature-2

feature-3

Planetary Ball Mill BM1150+ (Two Grinding Stations)

Introducing the LABINDIA Planetary Ball Mill BM1150+, designed for precise dry and wet grinding and mixing of soft, hard, brittle, and fibrous samples. This versatile mill ensures reproducibility of grinding results and meets the highest standards for colloidal grinding. Ideal for a range of applications, including mechanical alloying, the BM1150+ delivers high-energy input and fine grinding to nano levels, making it a key asset in any laboratory.

PRECISION GRINDING

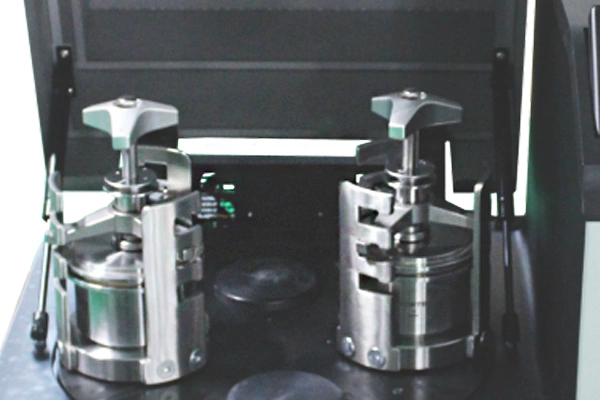

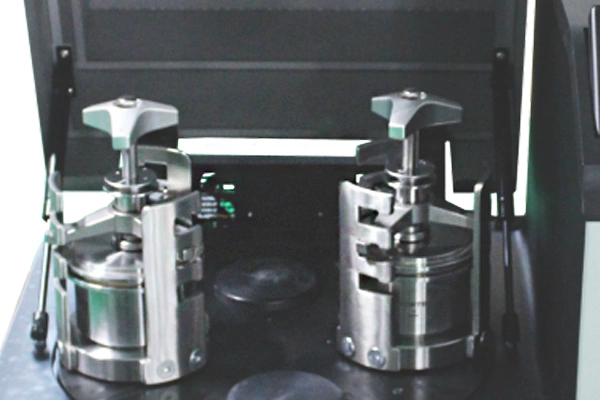

The BM1150+ combines two grinding stations and a range of jar sizes (12-250 ml) for efficient grinding. With the ability to achieve nano-fineness and provide reproducible results, this mill is perfect for applications requiring high precision and consistent quality. It supports both dry and wet grinding modes, ensuring versatility for different sample types.

Key Features

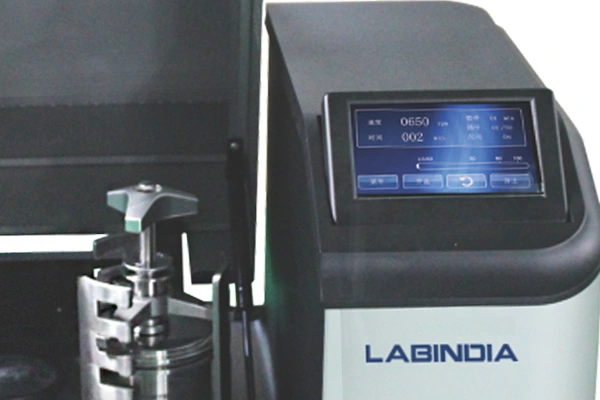

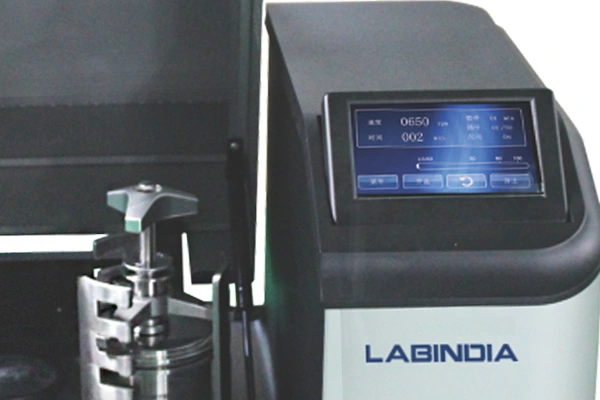

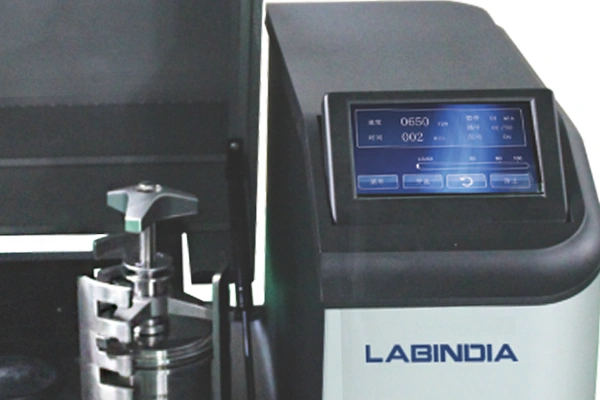

Equipped with a 7” LED color industrial touchscreen, the BM1150+ provides easy control over grinding parameters, including speed, time, and reverse direction. Its programmable settings store up to 10 SOPs, with cycle times adjustable from 1-99. The automatic direction reversal prevents agglomerations, ensuring uniform results across long-term operations. With its maintenance-free drive and efficient cooling system, this mill is designed for continuous, high-performance use.

USER-FRIENDLY OPERATION