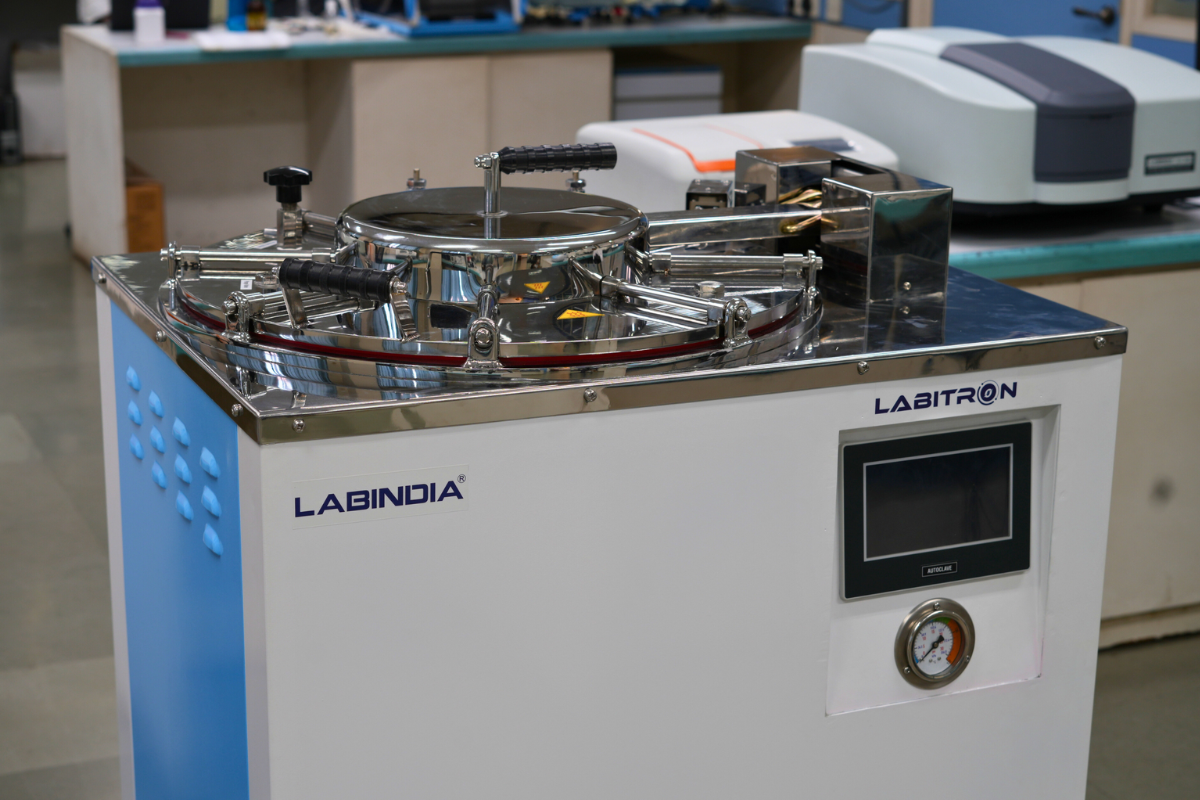

Labitron Autoclaves

Equipped with a Fully Automatic PID Controller, the Autoclave ensures automatic exhaust at the end of cycle (EOC), offering reliable sterilization with safety features like low water level cutoff, manual preset safety, and extra valves for secure operation. The system is designed for efficient, safe, and convenient use in various lab environments.

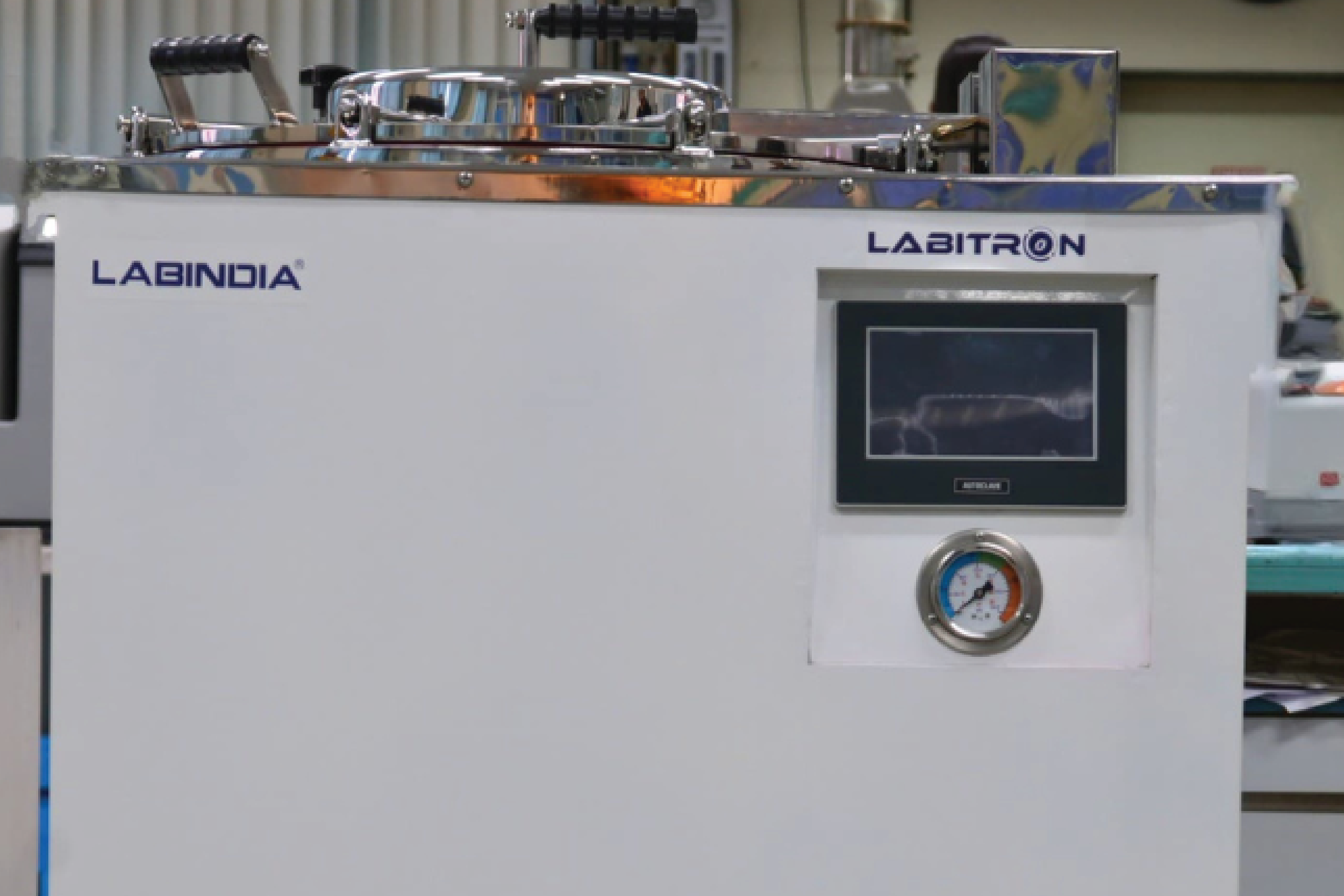

Labitron Autoclaves

Equipped with a Fully Automatic PID Controller, the Autoclave ensures automatic exhaust at the end of cycle (EOC), offering reliable sterilization with safety features like low water level cutoff, manual preset safety, and extra valves for secure operation. The system is designed for efficient, safe, and convenient use in various lab environments.

RELIABLE & SAFE STERILIZATION

This autoclave features a double-walled cylindrical shell, with top loading for easy access, and efficient sterilization cycles to ensure optimal performance. The process starts only once the lid is fully locked and will not open under pressure, guaranteeing safety during operation.

Key Features

The PID controller offers precise temperature and time management, with various features that protect the system from low water levels and overheating, ensuring longevity and smooth operation.

EFFICIENT CONTROL & DESIGN