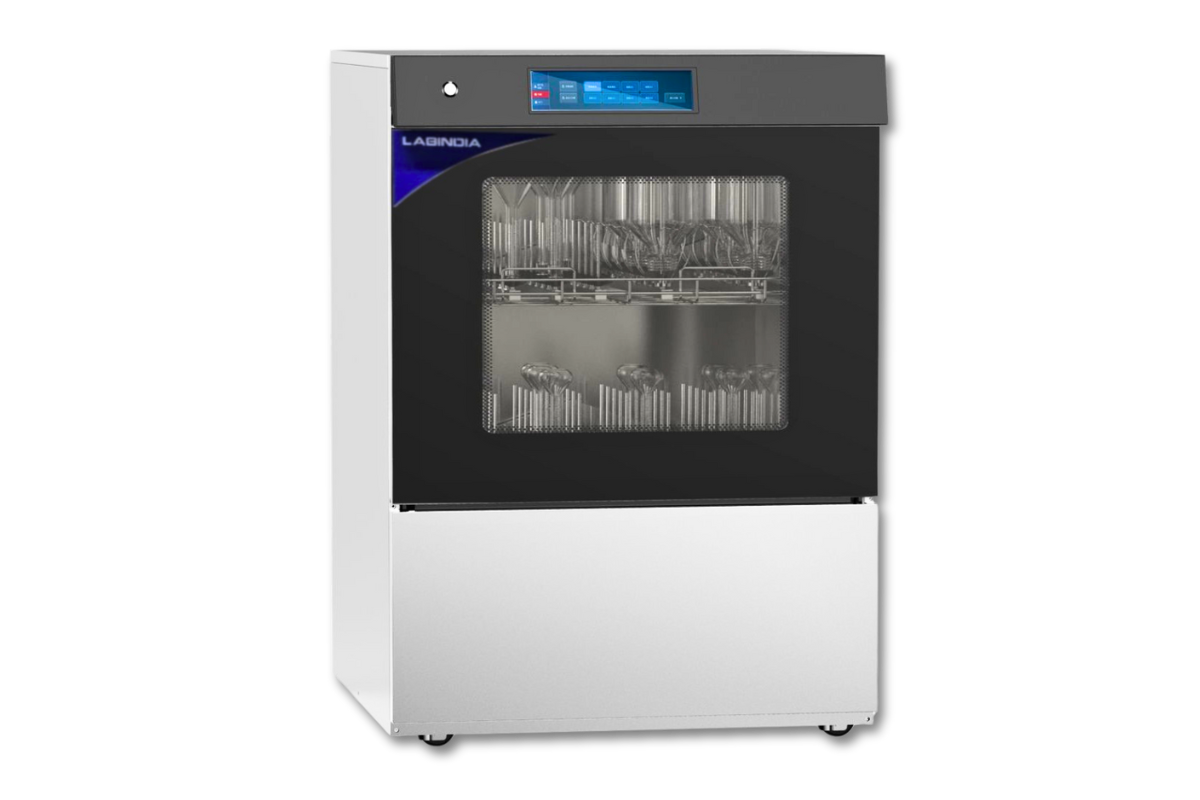

Glassware Washer

Know more about

Glassware Washer

Glassware Washers ensure efficient cleaning of laboratory glassware, enhancing productivity and compliance. These reliable systems are ideal for research and industrial laboratories.